A Sustainable Wheat Optimization Method to Overcome Volatility in Wheat Quality and Prices

Wheat ranks among the top three cereals in the world alongside rice and corn in terms of production and human consumption.

Matveeva Irina, Ph.D., Dr. Sc., Prof. Novozymes A/S

A quick look at wheat

Wheat ranks among the top three cereals in the world alongside rice and corn in terms of production and human consumption. Its popularity mainly stems from its ability to grow in a variety of soil and climatic conditions; from the southern regions of South America to the northern latitude of about 60°. But most importantly, from its unique ability to produce leavened bread and a multitude of baked products. Being the principal component of bread, quality of the wheat flour is vitally important. The wheat kernel, however, is highly heterogeneous in structure and composition and this heterogeneity arises from genotypic differences combined with environmental effects.

Global changes in climatic, soil and agronomic growing conditions further underline the fluctuating quality of wheat crops on a yearly basis. Significantly, many aspects of flour quality are a direct consequence of the quality of wheat used for milling.

Wheat prices today are at the highest levels since 2007. Events from February 24th have caused an unprecedented situation leading to an existential threat of the global wheat foods industry including farmers, farmer cooperatives, exporters, importer millers, bakers, and manufacturers.

Supply chain disruptions, exacerbated by the pandemic have also been adding to the surging prices

Harsh droughts, such as those in North America have resulted in a 30% reduction in their production. However, the US wheat price increase is not reflected in the mills’ flour prices. Dramatic wheat prices have increased by 50- 65%, whereas flour prices at bakeries are up by 10-20% only. Millers are already in a challenging situation where either miller or bakers are losing money (U.S Wheat Association, 2022).

In the 2021 season, supply decreased by 5.4% which initiated a new downtrend. The 2022 season forecast predicts another decrease of 10.0% which will contribute further to the downtrend. If realized, the continued downtrend will induce an upward price pressure (Mintec, 2022).

Numerous other factors also affect this key global commodity’s quality and supply. For example, the quality profile of the crop in Australia was impacted by a wet harvest, which resulted in a high proportion of the wheat crop being downgraded to low protein and feed grade wheats (ABARES- Department of Agriculture, Water and the Environment, Australia Government, 2022) while Argentina, the single largest wheat producer in South America has strong production output, but an export quota is in place.

The Black Sea region (Russia, Ukraine, Kazakhstan) is the major region for the world wheat market, and the current conflict means lowest ending stocks, disruption to shipping, escalation to sanctions and increased demand add to the pressure on price.

In conclusion, world demand for wheat is currently in an uptrend according to the latest USDA forecast. This is supported by the demand sectors. In the 2022 season, demand is expected to increase in all regions apart from China and Russia.

The world supply/demand balance is down trending monthly. This puts an upward pressure on wheat prices. So, the cost drivers for wheat are currently up trending which provides an upward price pressure (Mintec, 2022).

The wheat gristing cost optimization model – no compromise on final flour quality

Every flour mill faces a plethora of challenges affecting its business operations. Some of the challenges may include inconsistent flour quality, required enhancement of flour quality, raw material price fluctuations, wheat purchasing costs, non-optimal flour extraction rates, new product development, and the need to innovate.

In this article, we bring the relevant information that will help in optimizing the wheat grist cost without compromising on final flour quality, which results in unlocking the full baking potential of flour.

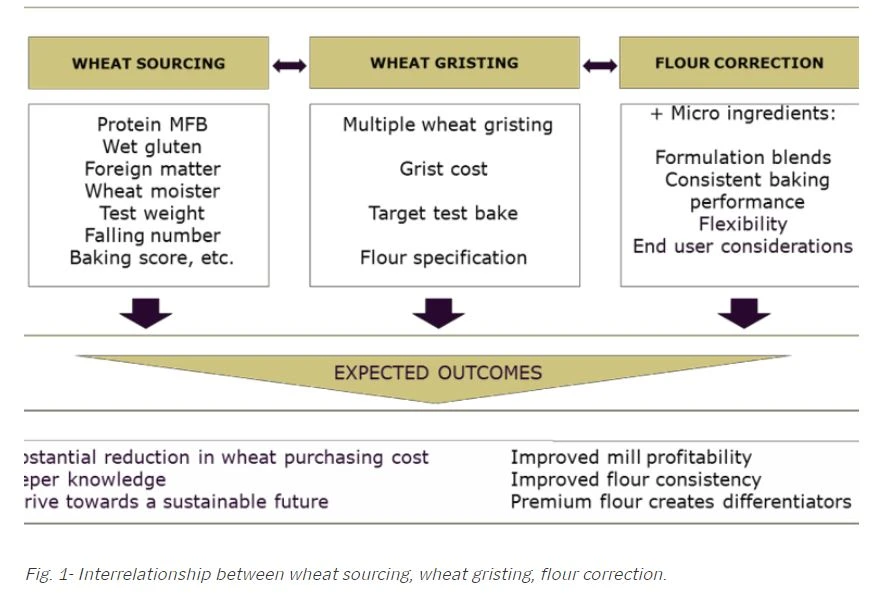

Over the years, wheat milling has adapted to this heterogeneity to optimize the transformation of wheat into different types of flours with different uses in food. All desirable business outcomes are connected to three main decision criteria: wheat sourcing, wheat gristing and flour correction.

The interrelationship between these three factors and business outcomes are depicted in Fig. 1.

Together, these factors and outcomes can help optimize costs, standardize flour performance, and support new product development.

Smart purchasing of wheat is vital for the profitable and sustainable running of any flour mill because it is intrinsically linked with grain price through mill operational protocols and customer expectations.

Wheat procurement and purchase, however, involve both risk and a considerable amount of investment both in time and money. The fact that wheat has become a major commodity in world markets results in high price volatility. Therefore, it becomes more important to purchase through reputable exporters or intermediaries. Inherent knowledge of the origin, source and specification of any given wheat is also extremely important.

Cost at first break is just one way of predetermining cost. There are many others – first break raw, protein on a moisture free basis (MFB), wet gluten (WG), extraction ratio and even baking score – which allude to end user considerations and expectations.

The primary driver behind sustainable wheat sourcing has always been to achieve a reduction in protein costs and to attain a positive result in mill profitability by doing so.

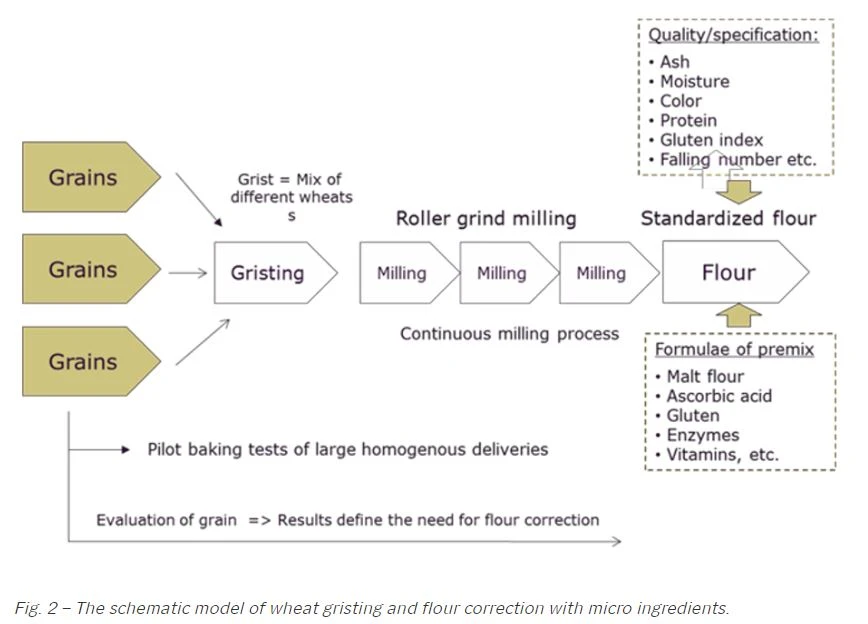

In fact, the combination of several wheats from various origins in the gristing process is fairly common practice in the milling industry.

The potential savings come by switching from a 100% high protein, more expensive wheat to one that contains a blend with a certain amount of lower protein, less expensive wheat. The spread in the FOB price and the resulting cost per ton of flour opens a window of opportunity, allowing an optimal combination to perform on an equal footing in terms of quality, performance, stability and fermentation tolerance. Experience has shown this can be achieved by incorporating micro ingredients to the value, which generates a delta saving being a substantial benefit to the bottom line (Fig.2).

Taking into account the procurement priorities or supply chain challenges context, baking enzymes are an attractive option for gristing considerations in flour milling process. The wise choice of enzymes micro dosages is capable to bridge the gap in wheat quality in most of the cases.

The well-defined enzymes’ complex makes it possible to address deliberations about switching from current approved wheat suppliers to the more tempting options which may be 5-25% less expensive without any compromise in quality. This is possible because of enzymatic solution performance predictability. This will not only drive down wheat purchasing costs, but also improves reliability while maximizing the profitability level in the milling industry.

Unlocking the full baking performance of flour with enzymes

In essence, the concept of enzymes being the key element of gristing model, unlocking full baking potential of flour is based on rationalizing and utilizing knowledge of wheat costing, wheat quality and understanding enzyme functionality to be able to produce flour with desired characteristics in a cost-effective manner.

The main drivers for flour correction include the following:

- inconsistent wheat quality arising from genotypic differences combined with agronomic growing conditions and environmental effects

- the need to standardize flour performance to produce bread or other wheat-based products with consistent quality

- lack of flexibility to improve flour quality in industrial bakeries

- end user requirements for different flours to produce an extensive range of products

- cost savings from grist optimization and flour performance upgrade.

There are several factors which should be taken into consideration when flour correction treatment is applied. These include the flour specifications and standards in the target market, the availability of a test bakery, availability of instrumentation for measuring flour quality (Farinograph, Alveograph, Mixolab, Falling Number Test, Extensograph, etc.), predominant dough making procedures and the assortment of baked products, local food ingredient regulations i.e., list of permitted food ingredients and flour improver habits in bread improver applications in industrial and artisanal bakeries (types, formulations, dosages, performance, etc.) and the main needs and concerns of flour among end-users in relation to the finished product requirements.

Success of flour correction depends on close cooperation between flour mills and flour buyers (industrial bakery, artisan bakery, pasta factory, biscuit factory, frozen dough producer, etc.), good knowledge of end user needs and requirements regarding flour quality, and expertise to manage flour functionality to achieve the desired properties.

Ingredients used at flour mills and bakeries are often the same. The main difference lies in the dosages range: 10-100 ppm at the mill; >100 ppm at the bakery. It is, therefore, critical to maintain dosage levels of enzymes being incorporated at the flour mill to moderate amounts to realize efficient flour correction and prevent their overdosing at the bakeries.

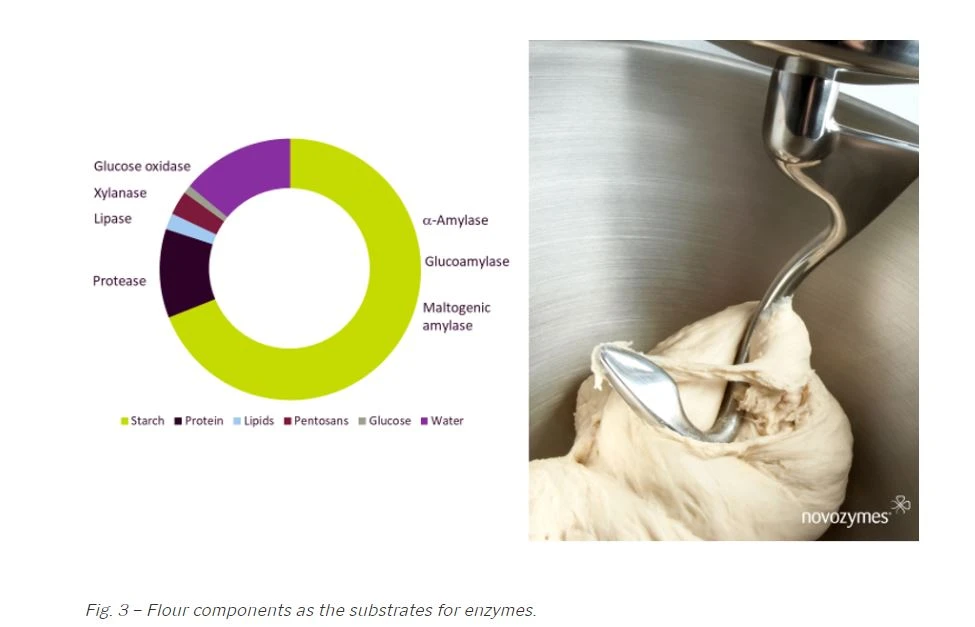

Unlocking the baking potential of flour refers to flour adjustment (correction, supplementation) with appropriate enzymatic solutions depending on wheat grist and initial flour quality and modifying its main components. These components include starch, non-starch polysaccharides, lipids, and proteins that help achieve desirable bread quality: volume, crust, crumb, bloom and so on.

Refined wheat flour, i.e., from the endosperm, contains 12-15% moisture, 65-70% starch, 7-16% proteins, including storage (gluten) proteins and water-soluble proteins, 1-3% non-starch polysaccharides, 1-2% lipids and 0.5-1.0% ash, or inorganic compounds. These flour components may be considered as substrates for modification by baking enzymes as shown in Fig. 3 to correct baking performance of flour, optimize the technological process parameters, attain needed dough properties, improve the quality of baked products, produce special flours, and achieve cost efficiency.

Fig. 3 – Flour components as the substrates for enzymes.

Enzymes are considered the most important ingredient to achieve consistent flour performance, better bread quality and optimize costs, based on their functionality of flour (Fig. 4) to help millers satisfy evolving customers’ needs and achieve cost optimization.

Additionally, enzymatic solutions help to produce a wide range of special flours with the additional benefit of longer-lasting freshness of bread, for applications in a wide variety of baked goods and food including cakes, biscuits, wafers, pasta, covering various needs and meeting the cost saving expectation.

Applications of enzymatic flour correction

Examples below demonstrate enzymatic flour correction and improved baking performance to help millers satisfy evolving customers’ needs and achieve cost optimization.

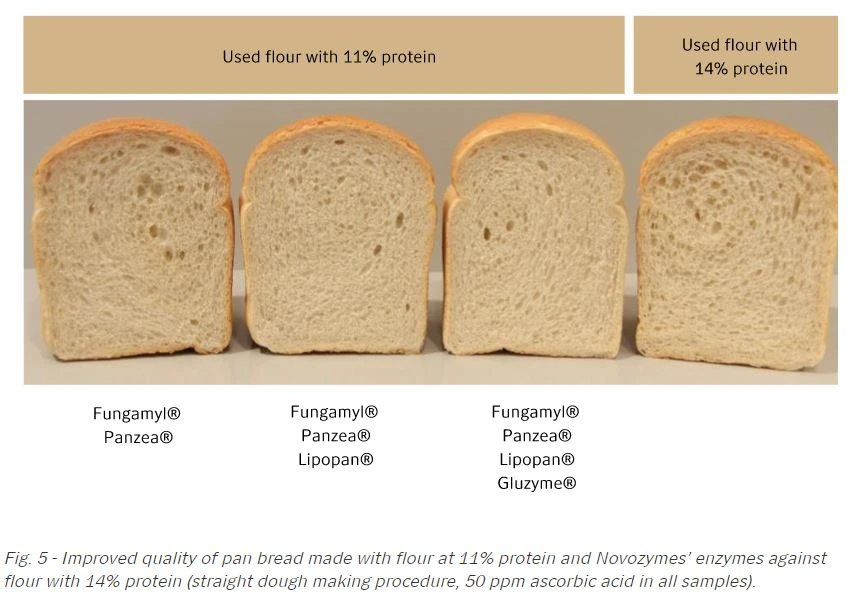

Fig. 5 demonstrates that the use of different combinations of Novozymes’ enzymes in a flour with 11% protein, results in an identical baking performance, compared to a flour at 14.5% protein.

Fig. 5 - Improved quality of pan bread made with flour at 11% protein and Novozymes’ enzymes against flour with 14% protein (straight dough making procedure, 50 ppm ascorbic acid in all samples).

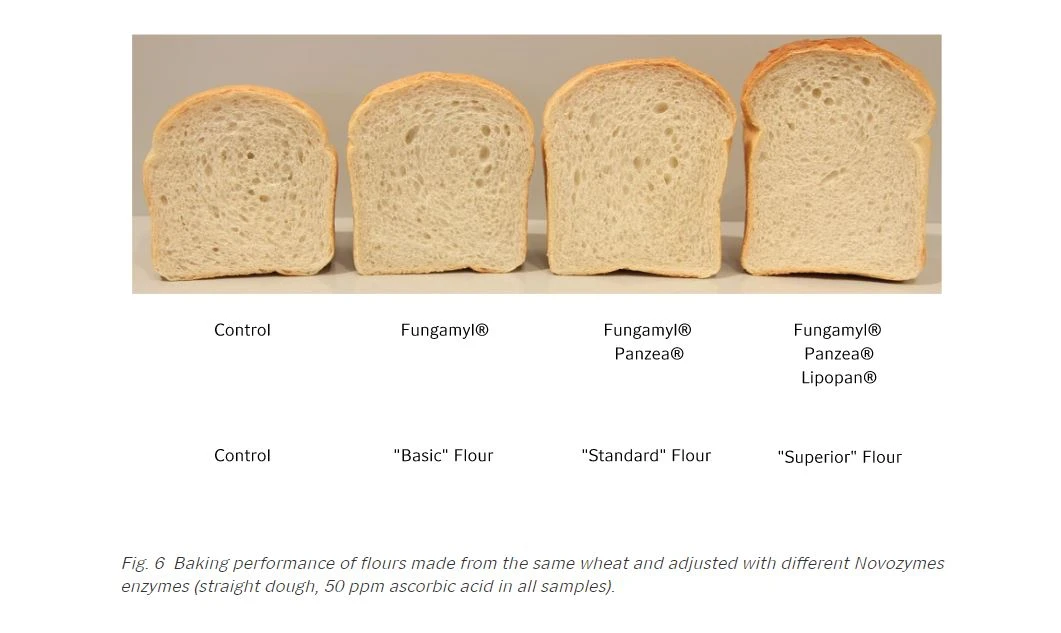

For companies considering differentiation of their flour in the market or reducing business complexity by decreasing the number of stocks keeping units, it is more feasible to create a ‘family’ of flours from a single grist delivering multiple flours, reducing SKU’s and production costs (as illustrated in Fig. 6). As illustrated in Fig. 6, it is possible to improve performance with additional enzymes (e.g., lipases and glucose oxidase), thus delivering several flour types which varying specifications have been achieved with regular adjustment of improvers which are blended in-house.

Fig. 6 Baking performance of flours made from the same wheat and adjusted with different Novozymes enzymes (straight dough, 50 ppm ascorbic acid in all samples).

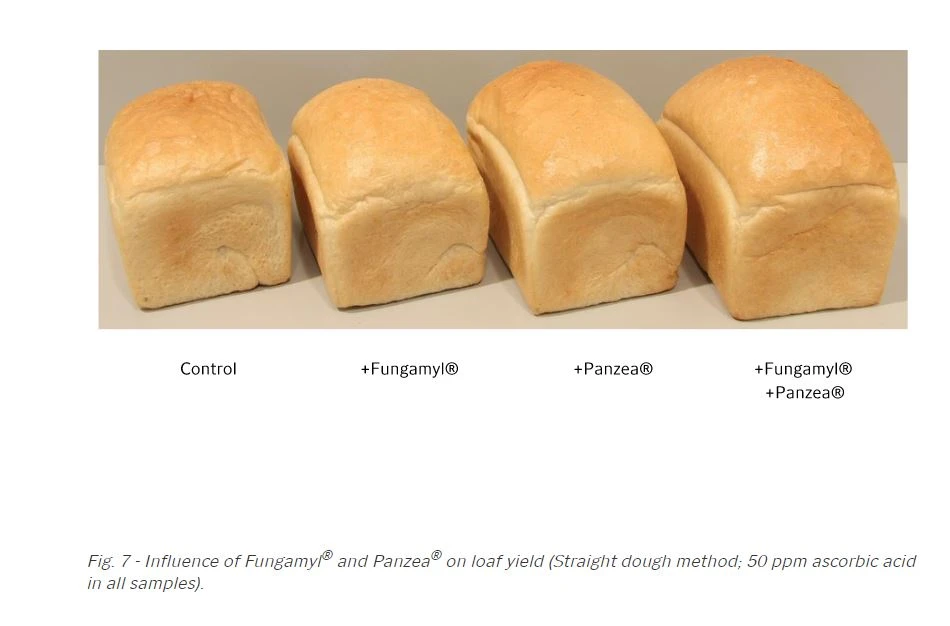

The dynamics of each milling and baking market are influenced by many factors, not least the objective of increasing yield which can be achieved by adding fungal α-amylase (Fungamyl®) and endo-xylanase (Pentopan® and Panzea®). Enzymatic solutions can further help escalate the loaf yield if bread is sold per piece as illustrated in Fig. 7.

Fig. 7 - Influence of Fungamyl® and Panzea® on loaf yield (Straight dough method; 50 ppm ascorbic acid in all samples).

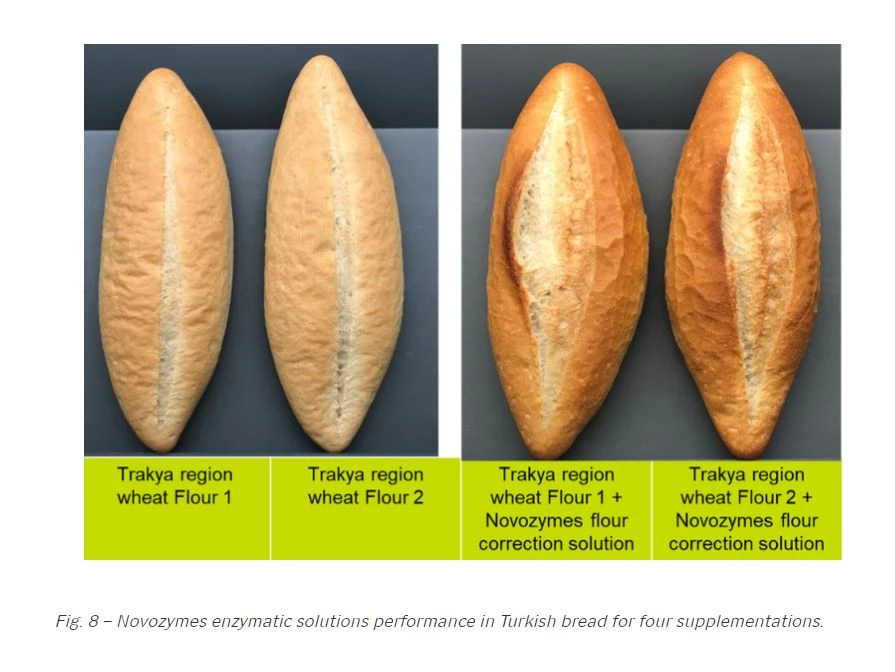

The flour correction of flour produced from wheat of Trakya region with Novozymes solutions, is shown on Fig. 8. The flour supplementation with Novozymes enzymatic cocktails, resulted in the superior baking performance of Turkish bread types, demonstrating appealing appearance, significantly better volume, excellent bloom and more intensive crust coloration.

This technique was accomplished with the well-equipped Novozymes Flour laboratory of Innovation & Technology Center in Istanbul by using modern equipment and tools (Flour mill, Mixolab, Inframatic, Farinograph, Alveograph, Extensograph, Glutomatic, Hagberg-Perten, etc.) to help conduct the detailed and deep analysis of wheat and flour quality. The solutions for flour supplementation are designed basing on the wheat and flour characteristics and targeted expectations.

Fig. 8 – Novozymes enzymatic solutions performance in Turkish bread for four supplementations.

Sustainable wheat sourcing as an approach towards wheat optimization

The cost drivers for wheat are currently up-trending which provides an upward price pressure. The shortage in wheat sources aggravated with varying wheat qualities and lower baking performance affects baked products quality, results in difficulties of manufacturing a large range of flour types and managing production costs.

Imagine using the sustainable wheat sourcing concept to optimize wheat sourcing costs due to increased flexibility in gristing, deep industry insights through exclusive collaboration with Novozymes Innovation & Technology Center (Istanbul) while actively utilizing the services of Novozymes to act as an ambassador.

Novozymes’ solutions are based on predictable baking performances that can be considered as part of the gristing model to unlock the baking potential of flour (Fig.9). By using the conceptual role of enzymatic solutions in gristing, look forward to optimization and reduction of gristing costs, sustain the various sources of the wheats, stabilize the baking quality of the final products while driving-up your profitability.

Acknowledgment

The author wishes to acknowledge the contributions of fellow Novozymes colleagues: European Technical Service Center Silvia Strachan, Regional Marketing Manager Nihan Ergen, Regional Sr. Communication Advisor Yiling Lu and last but not least, Hasim Sinik for his help with the Turkish translation.