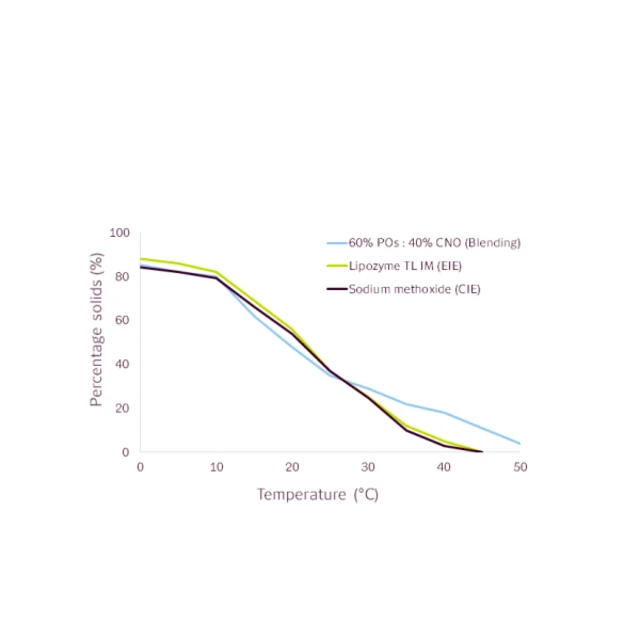

A similar melting profile to chemical interesterification

SFC curves for 60% palm stearin and 40% coconut oil blend.

Trans fats are linked with heart disease, so the demand for margarines and other products with healthier, heart-friendly trans fat-free oils and fats is growing. You can meet this demand with our safe, environmentally-friendly enzymatic interesterification (EIE) solution. The partially hydrogenated oils (PHOs) used in many processed foods are a major source of trans fats. Through enzymatic interesterification, you get the right shelf life, flavor and melting characteristics. You also get oils with a far better color profile than with chemical processes. All while eliminating trans fats from your products.

SFC curves for 60% palm stearin and 40% coconut oil blend.

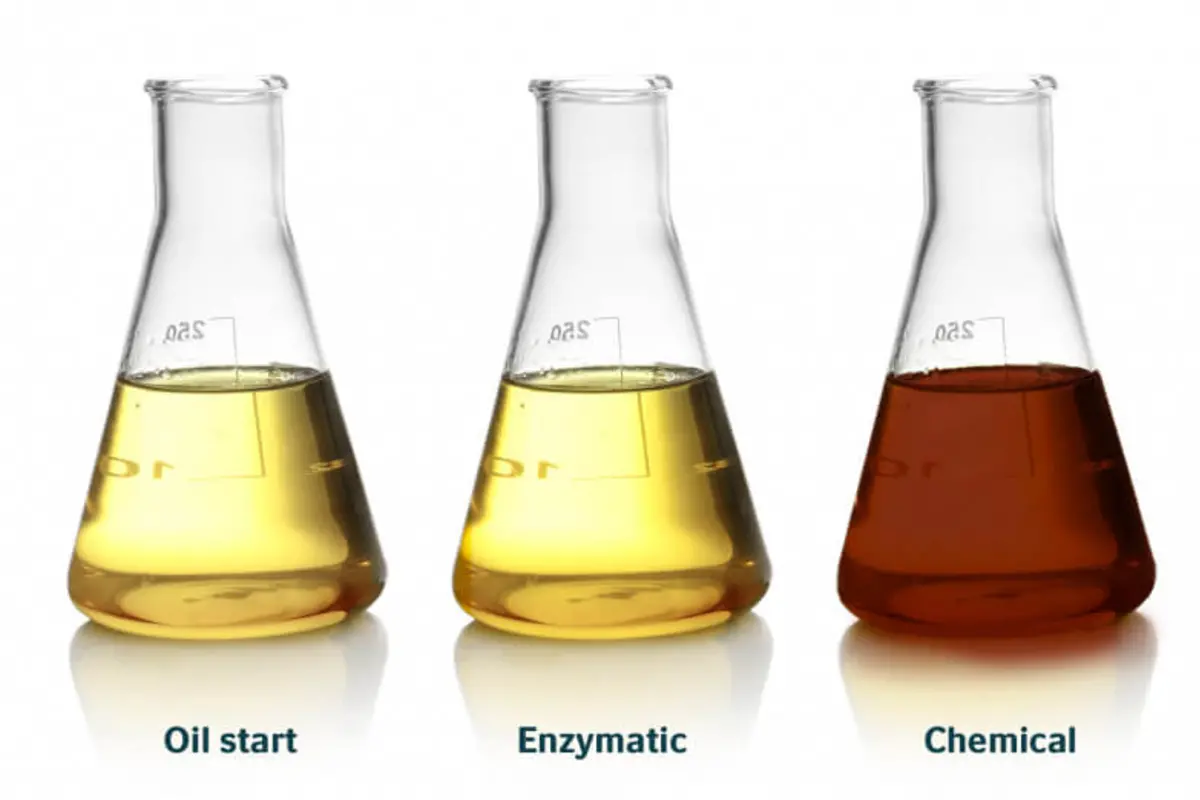

The flasks above show the clear difference in oil color when using enzymatic and chemical catalysis. The colors shown are after reaction and before purification.

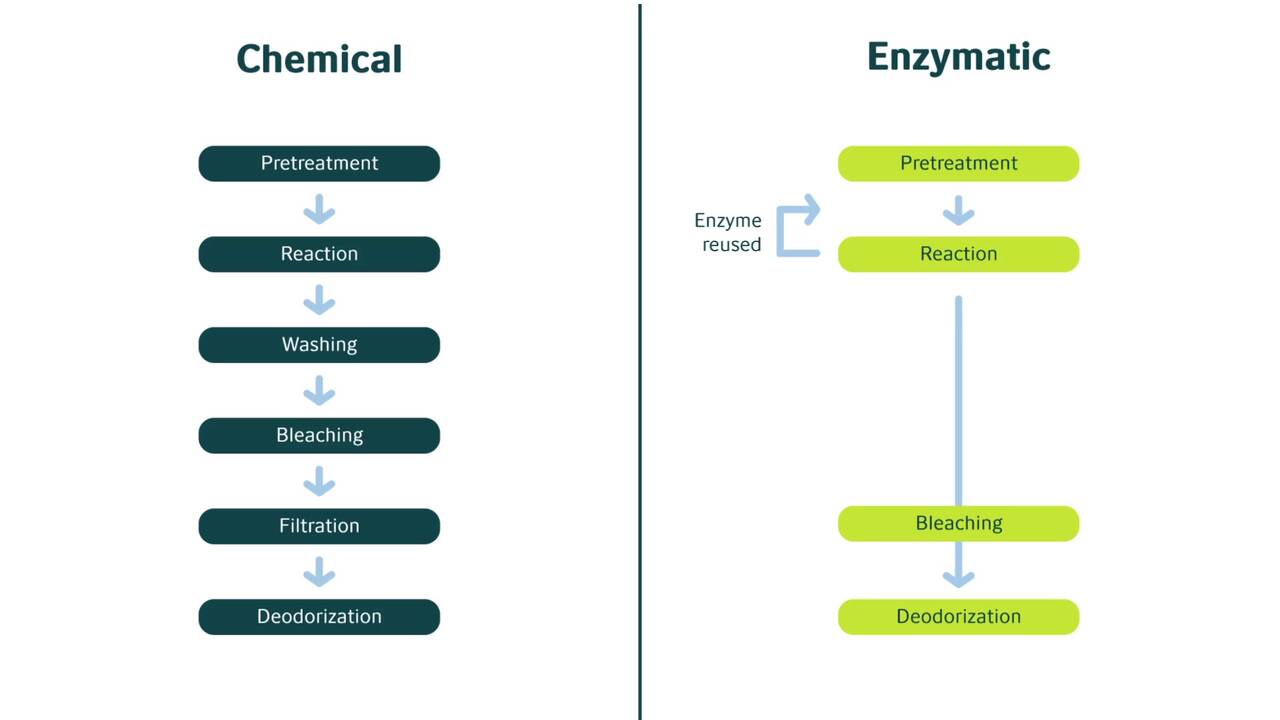

The chemicals used in chemical interesterification (CIE) are strong corrosive bases. They need careful handling to ensure worker safety. EIE is more cost-effective process with fewer steps that delivers higher yields. It also avoids harsh chemicals while reducing waste and by-products, making it more sustainable.

Trans fats are associated with heart disease, which leads to millions of deaths every year. All over the world, regulatory authorities are putting measures in place to reduce and even eliminate trans fats.

With enzymes, you can produce better-quality, heart-healthy, trans fat-free vegetable oils.

Get higher yields of better quality interesterified oils and fats with Lipozyme® TL IM. Enzymatic interesterification with Lipozyme® TL IM offers various advantages over chemical interesterification.

It allows you to produce high-quality, trans fat-free oils and fats. These are suitable for trans fat-free margarine and other products. All without using harsh chemicals or generating unwanted by-products.