Biodiesel from distillates

Generate more profit by making biodiesel from your byproducts

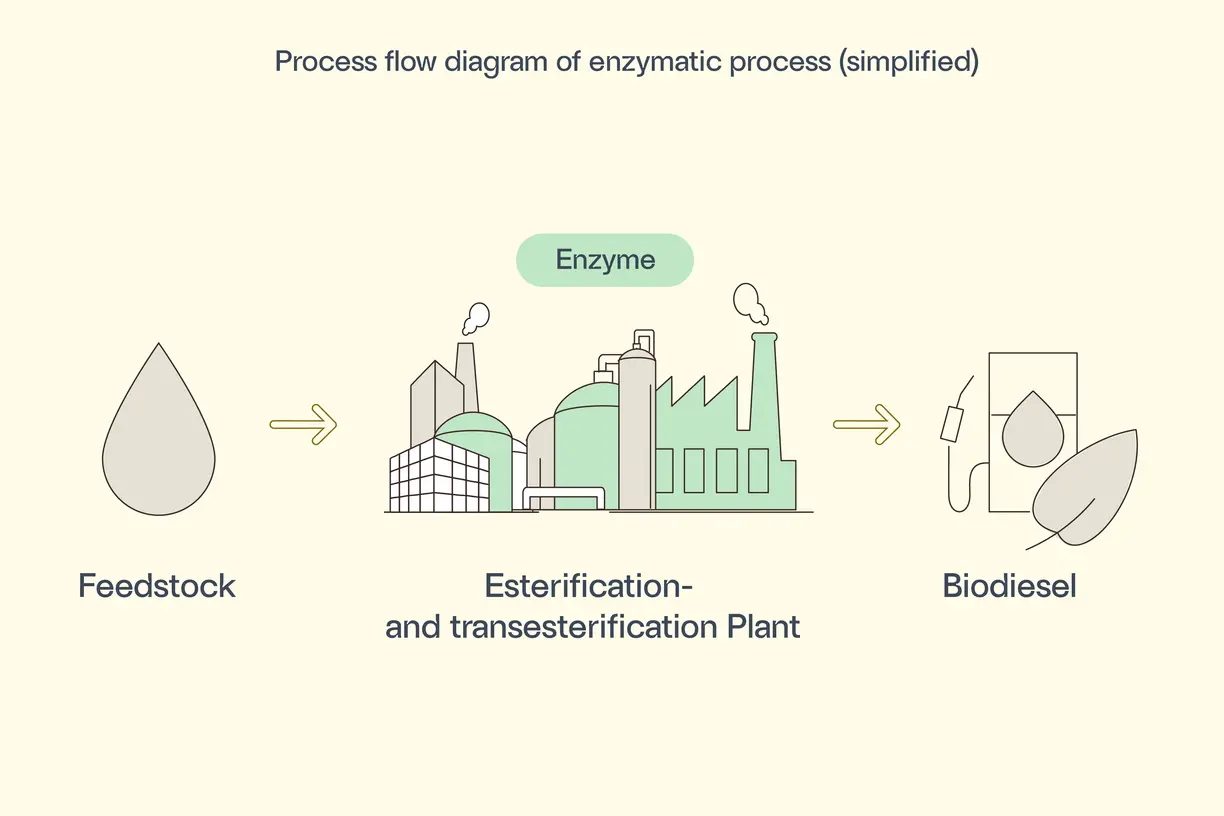

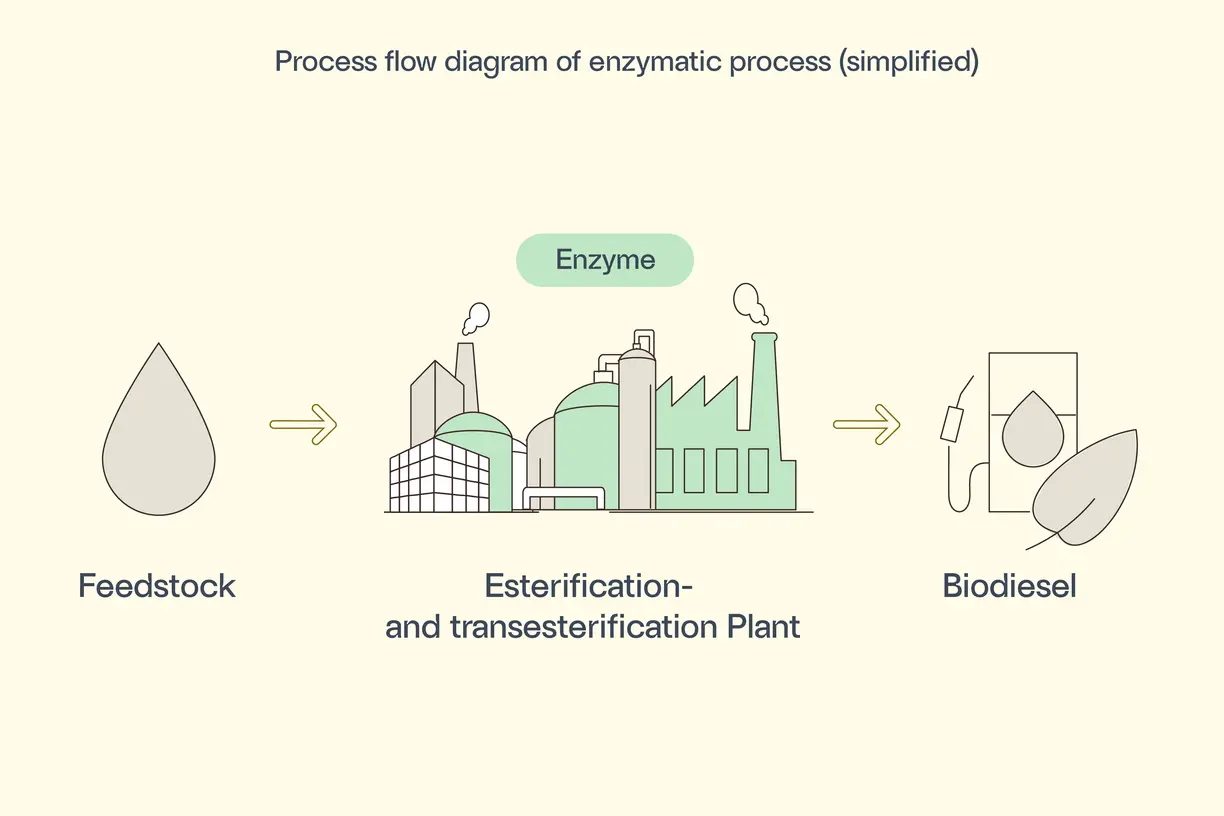

Like many the operators of many vegetable oil refineries, you’re looking for ways to upgrade your byproducts to biodiesel to turn an additional profit. In many cases, byproducts are converted to biodiesel using acid esterification or glycerolysis prior to chemical transesterification. However, these technologies require high costs for utilities and chemicals, byproducts or color formation, and significant CAPEX expenditures.

Enzymatic esterification and transesterification with Eversa® Transform 2.0 is well-proven to convert high-FFA feedstock, such as palm fatty acid distillate with up to 90% FFA, to in-spec biodiesel.

Biodiesel from distillates is accomplished using continuous stirred-tank reactors (CSTR) for a 150 TDP plant at ambient pressure and temperature, and delivers a number of benefits:

-

Up to €2.0 million more profit per year from byproducts

-

CAPEX as low as €12 million for a 150 TDP plant—much lower if existing equipment can be reused

-

An optimized enzyme dosage of <1 kg per ton of feedstock

With our FlexFit® process, Novonesis engineers can help you identify the best ways for your plant to maximize profits and transition to feedstock flexibility with our Eversa® Transform 2.0 biocatalyst.