Esterification of high-FFA feedstock for chemical biodiesel plants

Boost profits by processing high-FFA feedstock in your existing asset

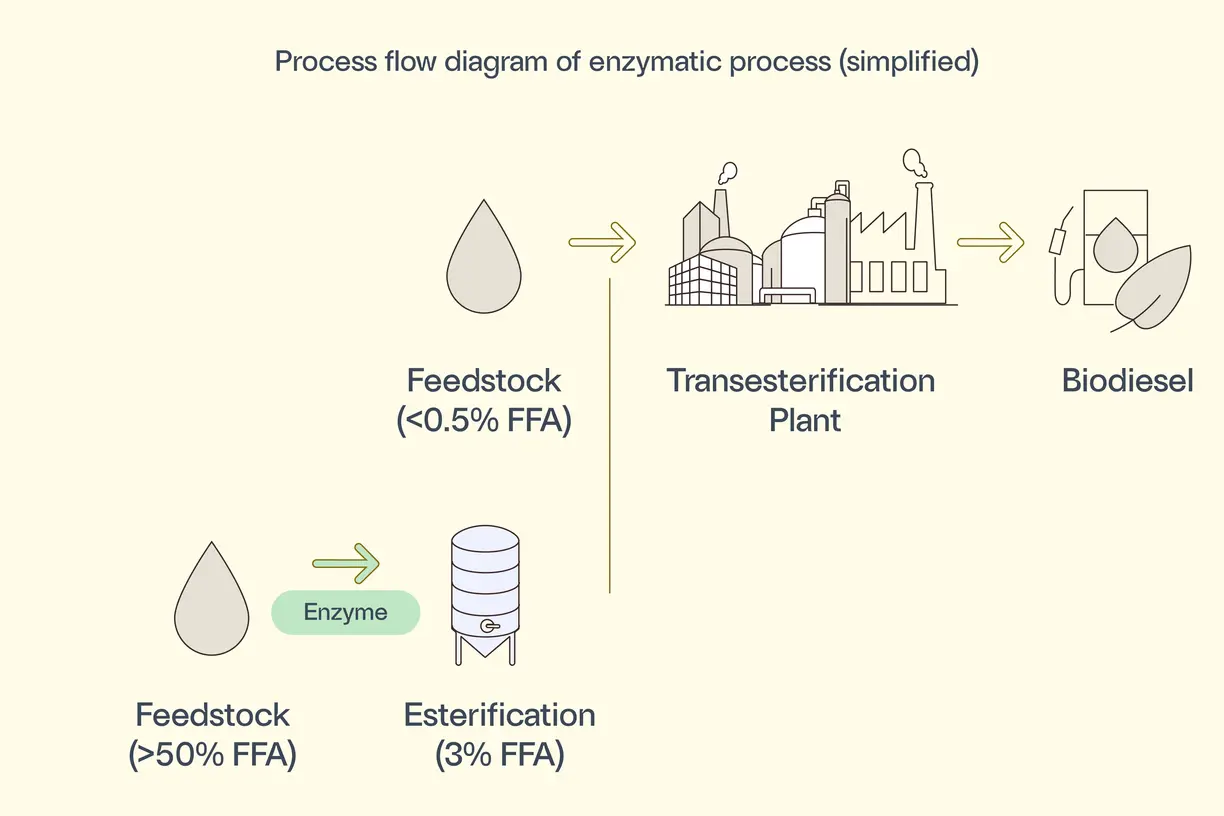

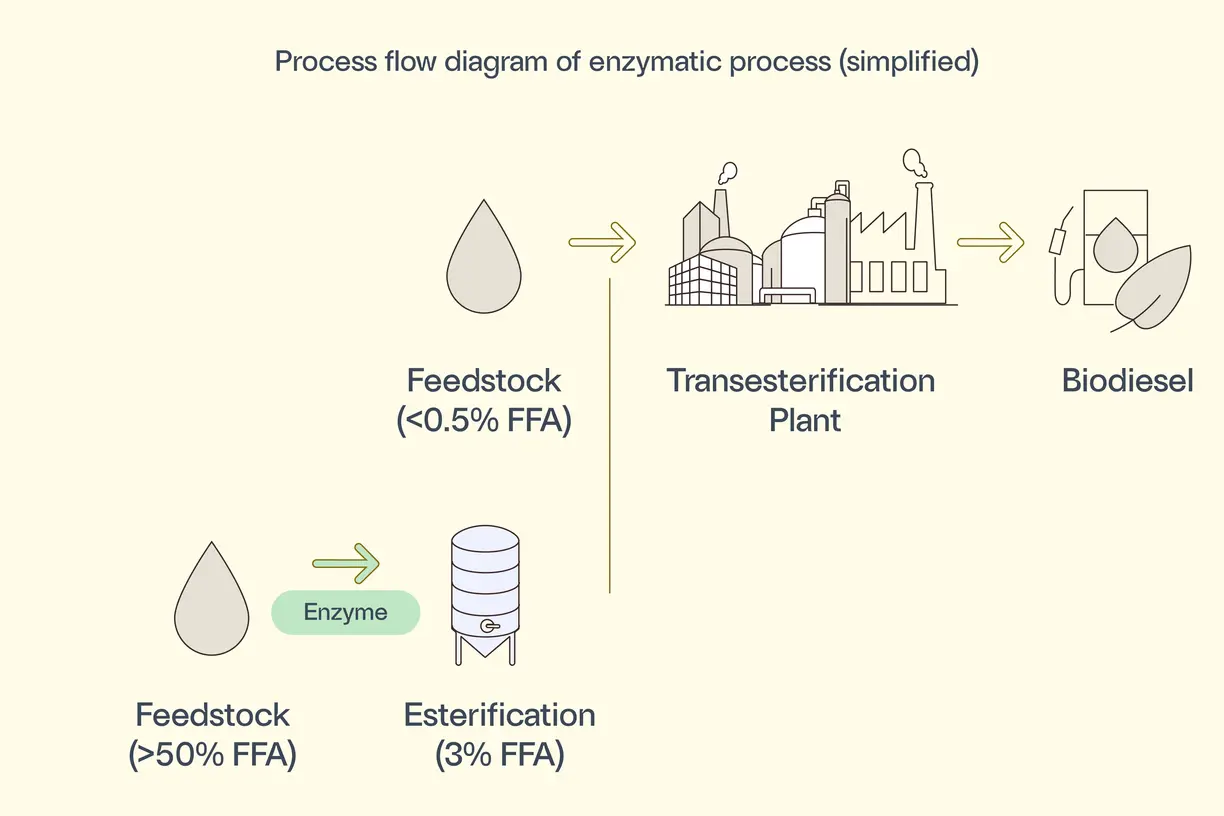

Like many biodiesel plant operators, you’re looking to start processing high-FFA feedstocks at the lowest possible capital cost. To accomplish this, many producers build acid esterification pre-treatment to process feedstocks in their existing chemical transesterification plants. However, acid esterification for high-FFA feedstocks requires a high acid dosage, long reaction times, and significant CAPEX expenditures to combat corrosion.

You can overcome these challenges and start processing high-FFA feedstocks prior to transesterification at a low cost and with minimal CAPEX with enzymatic esterification.

In this process, high FFA feedstocks are pretreated with Eversa® Transform 2.0 and then co-processed with chemical transesterification for on-spec biodiesel. Eversa® Transform 2.0 is well-proven to convert feedstocks with up to 90% FFA, such as fatty acid distillate, to crude FAME with 3-5% FFA.

Feedstock-specific pretreatment is accomplished using multiple bolt-on continuous stirred-tank reactors (CSTR) for a 150 TDP plant at ambient pressure and temperature, and delivers a number of benefits:

-

Up to €4.0 million more profit per year from high-FFA feedstocks

-

CAPEX as low as €2.0 million

-

A no-risk, bolt-on solution with no plant downtime

With our FlexFit® process, Novonesis engineers can help you identify the best ways for your plant to maximize profits and transition to feedstock flexibility with our Eversa® Transform 2.0 biocatalyst.