Let’s work together

Novozymes is your trusted pathway to new opportunities and growth in the baking industry. From sustainability to your bottom line, we’ve got you covered.

Let’s work together to meet your targets.

Recently, Novozymes and Akademetre conducted a study into consumer behaviour in the bread purchasing situation. The Consumption of bread in Turkey study collects data from 1,067 respondents across Turkey. For almost all consumers, it is imperative that packaged and unpackaged breads can stay fresh with natural methods. The levels of satisfaction with packaged and unpackaged breads are parallel.

Recently, Novozymes and Akademetre conducted a study into consumer behaviour in the bread purchasing situation. The Consumption of bread in Turkey study collects data from 1,067 respondents across Turkey. For almost all consumers, it is imperative that packaged and unpackaged breads can stay fresh with natural methods. The levels of satisfaction with packaged and unpackaged breads are parallel.

Organized industrialization of a staple food which is consumed by more than 1.7 billion people every day and its production which dominates in the Middle East and North Africa might also be able to benefit from longer freshness levels, while keeping consumers satisfied.

Unsurprisingly, our studies have also shown us that 75% of consumers claim freshness is an important factor when purchasing flatbread. The waste of flat bread has become a significant return challenge. Estimated daily flat bread waste is around 60.000 meters2. To put the figure in perspective, that is seven times the height of the Mount Everest (Fig. 1).

Fig. 1- Schematic of flat bread waste vs. Everest height.

Besides flatbread wastage, data from Turkey's Bread Producers Federation also reveals that between 10-20% of the 120 million loaves of bread produced daily is wasted and thrown out by consumers.

Regardless of the types of bread, consumers will often use more than one criterion when making their decision. If the first and second priority criteria are combined, then half of all consumers always consider the ’softness and springiness’ of bread as a deciding factor in their brand choice.

In fact, 1 out of every 4 consumers states that they are willing to pay higher prices for a bread that keeps its freshness for a longer time. Thus perception of freshness and health concern must be balanced and it is important to extend shelf life with natural ways.

Consumer behaviour is changing due to coronavirus lockdowns in many countries, typically leading to consumers stocking up on certain groceries. Typically, restaurants, cafés, canteens, educational institutions and workplaces have been closed during lockdowns in most countries. This has led to families buying more bread, fuelling the demand for pre-packaged fresh bread.

Consumers not only buy prepacked bread that can stay fresh longer; they also buy it because they care about hygiene as prepacked bread gives consumers the impression that the bread seems ‘safer’. Above this, consumers are willing to pay more for baked goods that are freshly baked and only contain natural ingredients.

A baker's worst fear is stale and dry goods, and one of the main reasons consumers throw their bread out is because of hardness and dryness. Every year, a staggering one-quarter to one-third of all food produced for human consumption goes to waste.

About 85 million tons of wheat flour is used every year in baking industry. It is assumed that roughly 10% of the waste occurs at industry and distribution level and up to 18% of bread is thrown away because of consumer non acceptance. Bread staling does remain responsible for huge economic losses to both the baking industry and the consumer (Fig. 2).

Fig. 2 - Schematic model of bread waste occurring (Data is for Flanders, Belgium. Source: Mintel GNPD).

The expected duration for bread to stay naturally fresh according to consumers is averagely 6-8 days.

Bechtel and others (1953) defined staling as “a term which indicates decreasing consumer acceptance of bakery products caused by changes in crumb other than those resulting from the action of spoilage organisms”. Consumers’ main preferences are extended shelf life and freshness for long period. In fact, from our earlier study, we found that according to consumers, the expected duration for bread to stay naturally fresh is averagely 6-8 days. The possibility of bread fresh keeping a few days longer could save 2 million ton of flour per year.

The mechanism of bread stalling is not known with great certainty although as reported in numerous publications, these changes in texture are due to modifications in configuration of the highly branched amylopectin molecules, either due to its reversion from the swollen, amorphous, gelatinized state into their native, rigid, crystalline state or perhaps, to an increase in the number of complexes formed with the gluten protein in flour.

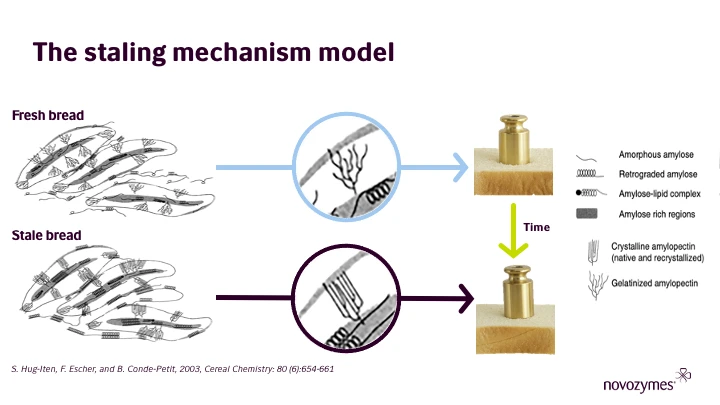

The schematic model, shown in Fig. 3, describes structural features of starch in bread.

Fig. 3 - The bread staling mechanism model (S. Hug-Iten, F. Escher, and B. Conde-Petit, 2003, Cereal Chemistry: 80 (6):654-661).

During baking, the native crystallinity of amylopectin is melted, and in fresh bread crumb, amylopectin is in an amorphous state. Reorganization of amylopectin influences mainly the rigidity of the granules because the polymer is located inside the swollen starch granules. Reorganization of amylopectin results in the formation of double helices of the outer branches, which are packed into crystallites. Amylopectin crystals act as physical cross-links in the continuous starch network, which lead to increased rigidity. The observation on the formation of ordered birefringent amylose structures leads to the conclusion that reorganization of amylose is also important for firmness. The formation of ordered amylose structures in the starch granule centres contribute additionally to the rigidity of granules.

Based on the present model, it can be concluded that both amylose and amylopectin form crystalline zones. Formation of cross-links by hydrogen bonds and entanglements between amylose and amylopectin have an impact on the mechanical strength of the interfaces between the amylose-rich and amylopectin-rich zones, which in turn influence the mechanical properties of bread.

A major effect of staling is the increase in crumb firmness and the loss of fresh crumb springiness or elasticity over time.

We patented and introduced a new and rather unique maltogenic α-amylase called Novamyl® in the late 1980s. Over the years, this transformative technology has saved around 80 billion loaves of bread from being thrown out, saved 650,000 tons of plastic packaging from ending up in the trash, and 45 million tons of CO2 from being emitted.

Allowing bakers to deliver better quality and longer-lasting baked goods from more than three whole decades now, has led to the need for less bread to be thrown away, wasted, or returned - resulting in a positive effect on the whole baking value chain. In fact, our range of freshness solutions help a wide range of baked goods including breads, tortillas, flat breads, and cakes stay fresh, even after storage. Extended freshness maintains the great quality while also reducing food waste.

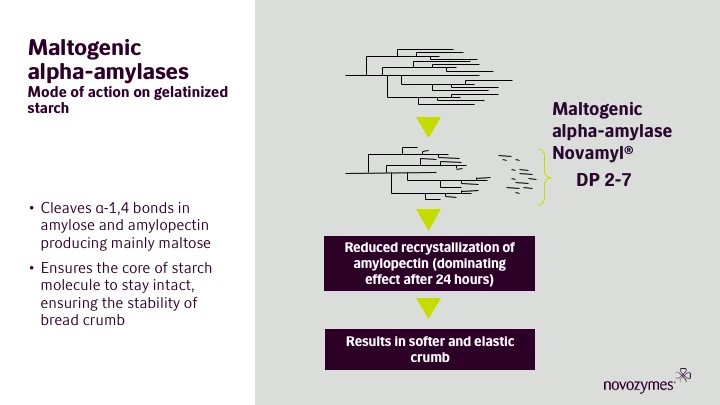

Novozymes’ maltogenic alpha-amylase has properties that made it much more efficient for extending the shelf-life of bread. It is this enzyme that forms the basis for most enzymatic shelf-life extenders in the market. Maltogenic α-amylase is active after the starch gelatinization temperature but is functionally inactivated by the time the bread exits the oven. What makes this enzyme particularly unique is the way it modifies the starch molecule. Instead of shattering the amylopectin the maltogenic amylase leaves its primary structure intact, generating small DP2-DP7 molecules (mainly maltose and some number of oligosaccharides and small dextrins) from the ends of starch molecules (Fig.4).

Fig. 4 - The mode of maltogenic alpha-amylase action.

This results in starch granules that not only stay soft longer due to the reduced rate of retrogradation and recrystallization but retain their inherent resiliency and keep it for a longer period of time due to their maintained integrity.

Meanwhile the baking industry needs differentiation – in an ocean of “soft” claims: “softer”, “softer as ever”, “softer recipe ever”, “softer and tastier”, “extra soft”, “chevy and soft”, “soft and tender”, etc.. The differentiation of freshness perceptions creates an opportunity for innovation here by creating the portfolio of solutions to meet different consumers’ and producers’ expectation in bread quality.

Our portfolio of baking enzymes builds on our expertise and have demonstrated superior performance a wide range of baked goods, including improvement of crumb softness and elasticity during long periods of bread storage when compared to emulsifiers among others. Delivering extra softness and a higher elasticity or resilience is also possible, helping industrial bakers to produce high-quality bread with a more moist and tender texture.

In short, maltogenic amylases solutions are helping us to build a portfolio based on the different values propositions depending on market insights, producers’ needs, consumers preferences.

In Novozymes, we constantly seek new ways to connect with our customers. We aim to bring value in a more flexible manner through online services and tools designed to be easy to use, inspirational and available whenever our customers need it. One of our first digital tools for the baking industry, SmartBake®, a dosage prediction tool for fresh-keeping enzymes, was launched to help customers with their fresh-keeping dosage trials by providing quick and easy access to the right enzymes and dosage. This clever tool enables baking customers to get instant technical recommendations on which enzyme and corresponding dosage ranges to use when baking a specific bread.

The Novozymes Innovation and Technology Center (ITC) has also opened in Istanbul. The ITC features state-of-the-art, locally relevant equipment, including an industrial scale flatbread line. It gives the opportunity to share our solutions, technology, and know-how up close to customers in the Middle East and other regions, opening up new partnerships and possibilities; to provide customers and partners with easier access to our regional R&D and marketing expertise, and over time, bring value to local communities and markets. It is one of the most effective way to do that is to move into their neighbourhood and invite the customers into ITC to share our world with them and understand their world better.

The continuous customer involvement and co-creation with the customers are the foundation that will continue and help build, keep, and develop strong partnerships. It is also how we make sure to develop and focus on the things that matter the most to our customers.

Novozymes is your trusted pathway to new opportunities and growth in the baking industry. From sustainability to your bottom line, we’ve got you covered.

Let’s work together to meet your targets.